How to Select Durable Industrial Hardware for Your Needs

- pmmwebmanager

- Dec 19, 2025

- 3 min read

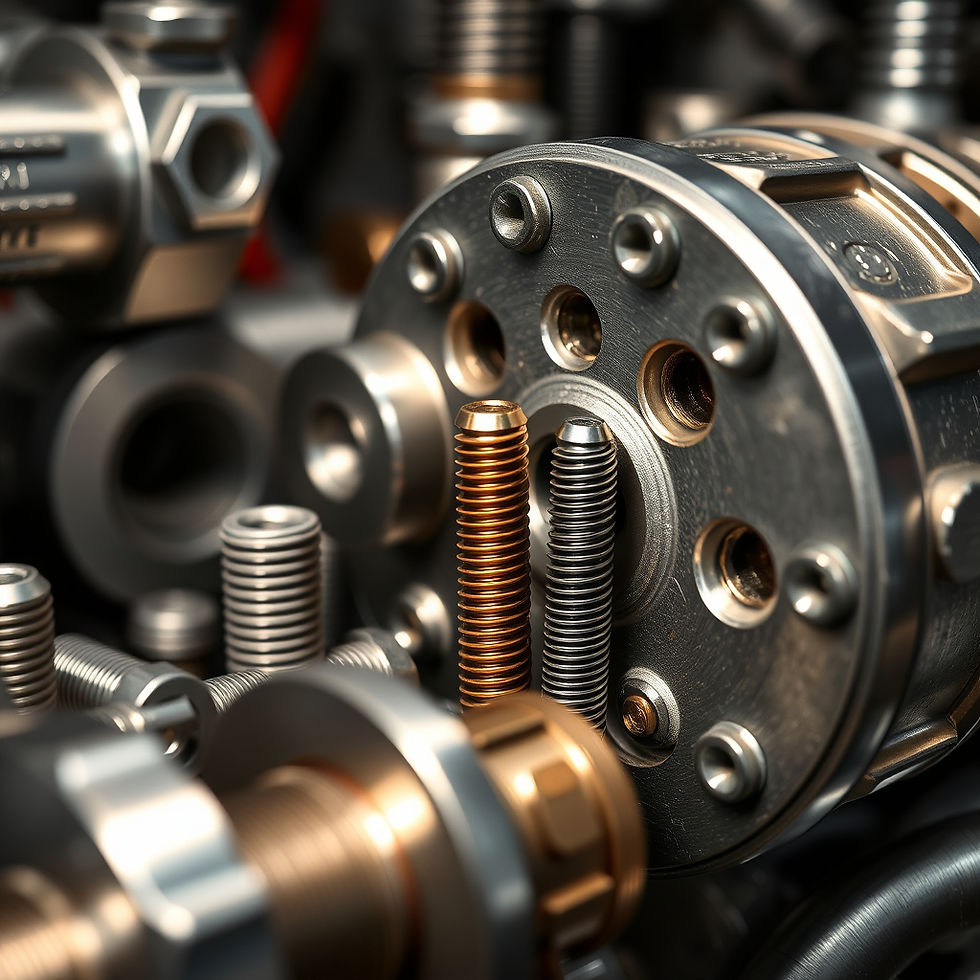

When it comes to running a successful operation, the right hardware can make all the difference. We’ve learned that choosing durable industrial hardware is not just about picking the toughest-looking parts. It’s about understanding your specific needs, the environment, and the long-term benefits. Let us walk you through how to select hardware that stands the test of time and keeps your projects running smoothly.

Why Durable Industrial Hardware Matters

Durability is the backbone of any industrial setup. When hardware fails, it can halt production, increase costs, and even compromise safety. We always prioritize hardware that can withstand harsh conditions, heavy use, and time. Here’s why durable hardware is a game-changer:

· Cost Efficiency: Less frequent replacements mean lower expenses.

· Reliability: Consistent performance reduces downtime.

· Safety: Strong materials prevent accidents and failures.

For example, in manufacturing plants where machines run 24/7, using subpar bolts or fasteners can lead to breakdowns. Investing in high-quality, durable components pays off quickly.

How to Identify Durable Industrial Hardware

Not all hardware is created equal. To find durable options, we focus on several key factors:

Material Quality

Materials like stainless steel, alloy steel, and hardened metals offer superior strength and corrosion resistance. For outdoor or marine environments, stainless steel is often the best choice because it resists rust and degradation.

Manufacturing Standards

Look for hardware that meets or exceeds industry standards such as ASTM, ISO, or ANSI. These certifications ensure the product has been tested for quality and performance.

Design and Finish

Hardware with precision design and protective finishes (like galvanization or powder coating) lasts longer. These finishes protect against wear, corrosion, and environmental damage.

Supplier Reputation

We always source from trusted suppliers who specialize in industrial-grade products. For instance, industrial hardware from Ossco Distribution is known for durability and reliability.

Testing and Warranty

Products backed by rigorous testing and solid warranties give confidence. It shows the manufacturer stands behind their hardware.

Choosing the Right Hardware for Your Application

Every project has unique demands. Here’s how we match hardware to specific needs:

Load and Stress Requirements

Calculate the load your hardware must bear. For heavy machinery, use high-tensile bolts and fasteners designed for extreme stress. For lighter applications, standard-grade hardware may suffice.

Environmental Conditions

Consider temperature, humidity, chemical exposure, and vibration. For example, in chemical plants, corrosion-resistant materials are essential. In cold storage, hardware must tolerate freezing temperatures without becoming brittle

Installation and Maintenance

Choose hardware that’s easy to install and maintain. This reduces labor costs and downtime. Some hardware comes with self-locking features or coatings that minimize the need for lubrication.

Compatibility

Ensure the hardware fits with your existing equipment and meets your operational standards. Mismatched parts can cause failures or inefficiencies.

Practical Tips for Sourcing Durable Hardware

We’ve found these tips invaluable when sourcing hardware:

1. Buy in Bulk from Trusted Suppliers

This often reduces costs and ensures consistent quality.

2. Request Samples and Test Them

Before committing, test samples in your environment.

3. Keep an Inventory Log

Track usage and replacement cycles to anticipate future needs.

4. Stay Updated on New Technologies

Innovations like advanced coatings or composite materials can offer better durability.

5. Consult with Experts

Don’t hesitate to ask suppliers for advice tailored to your application.

Maximizing the Lifespan of Your Hardware

Durability isn’t just about the product itself. How you use and maintain hardware matters too. Here’s what I recommend:

· Regular Inspections: Catch wear and tear early.

· Proper Installation: Follow manufacturer guidelines precisely.

· Routine Cleaning: Remove dirt, grease, and corrosive substances.

· Timely Repairs: Replace damaged parts before they cause bigger issues.

· Use Correct Tools: Avoid damaging hardware during installation or maintenance.

By combining durable hardware with good practices, you extend the life of your equipment and improve overall efficiency.

Partnering with the Right Supplier

Finding a reliable supplier is crucial. You can trust Ossco Distribution because we specialize in durable and efficient products. Our expertise helps businesses adapt to new technologies while growing their market presence.

When you work with a supplier who knows your industry and offers quality products, you gain a competitive edge. We can provide tailored solutions, quick delivery, and ongoing support.

Your Next Step Toward Reliable Hardware

Selecting durable industrial hardware is a smart investment. It protects your operations, saves money, and boosts productivity. Start by assessing your needs, researching materials, and partnering with a trusted supplier. Remember, the right hardware is the foundation of your success.

Explore options, ask questions, and don’t settle for less. Your projects deserve the best tools to thrive! Contact us at 401-461-6900, sales@osscobolt.com or learn more at www.osscodistribution.com.

Comments